TC-1450

| Features | ||

|

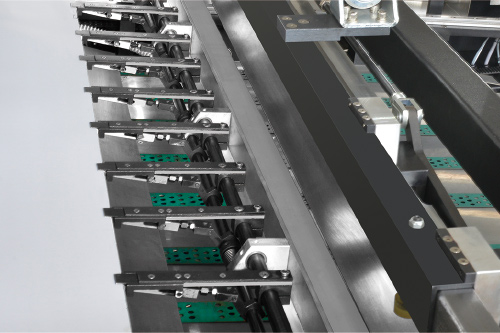

Receiving part One switching choose the cylinder with receiving part or normal cylinder without receiving part, which is best choice for ultra thickness substrate, receiving part seamless connection with cylinder along the cylinder’s movement track. Substrate printed flat, no bending no deformation, Downward retractable teeth to prevent scraping screen mesh |

|

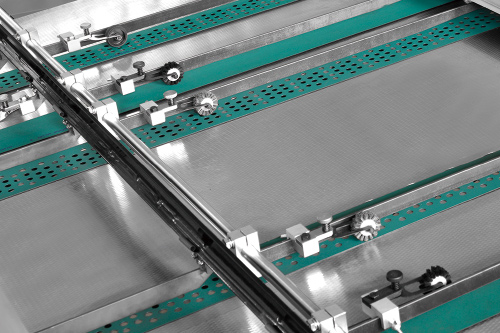

| Printing table frame Three direction electric registration electric screen frame micro adjustment system far away electric screen frame three axis adjustment directly input adjustment stroke Adjust in place by one step, convenient and practical. |

|

|

|

Substrate feeding System Drive universal shaft : The power supplier of whole feeder system Feeding board: Deliver the substrate to front lay stably Substrate separated blower: Separate the substrates for sucking the first one much more better. Substrate separated sucker: Make the first substrate departing from the pile until the sucker catch it, meanwhile the pressing feet press down to keep the following substrate stably. Substrate delivery sucker: Suck the substrate and deliver it until the receive roller can hold it Substrate receive roller: Hold the substrate come from the delivery sucker, and deliver forward under the drive of delivery roller. |

|

| Technical data | ||

|

||

| TOP > | ||