TC-105

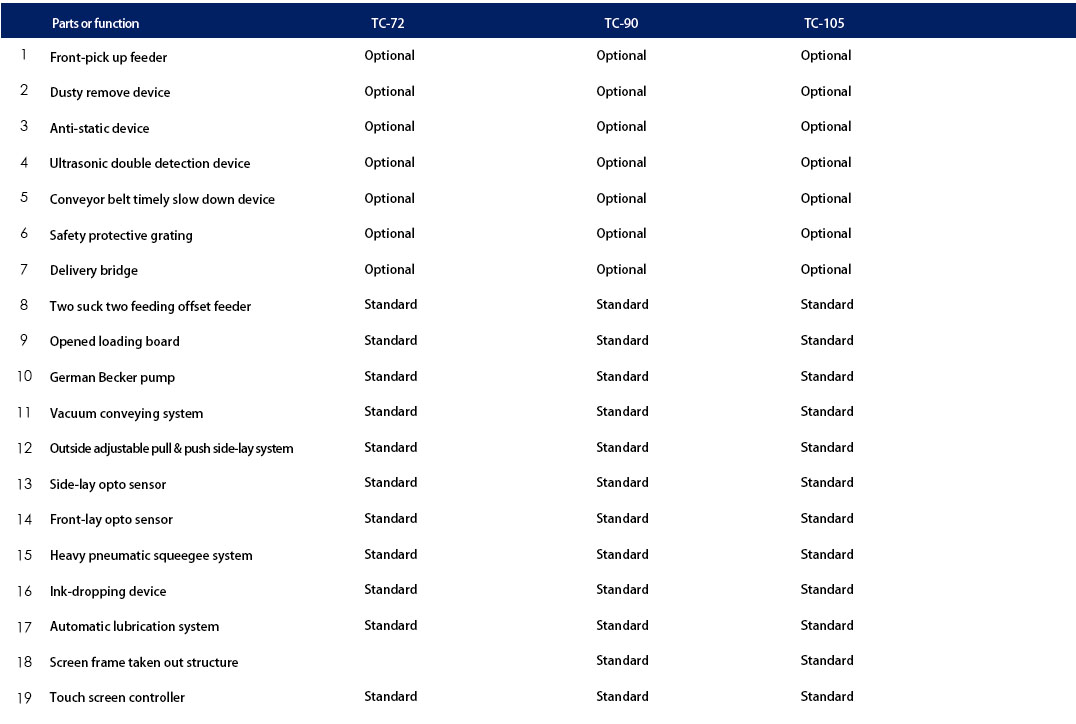

| Features | ||

| TC+TC-UV+TC-S TC105 Full Automatic Stop Cylinder Screen Press is the new designed patented machine, with advanced design and production technology, combine with German and Japanese technology. It adopts classical stop cylinder technology, equipped with heavy pneumatic squeegee system, the max. speed can be 4200sheets/hour. It is suitable for screen printing of ceramic and glass decal, advertisement, package printing, brand, textile transfer, electric etc. |

|

|

|

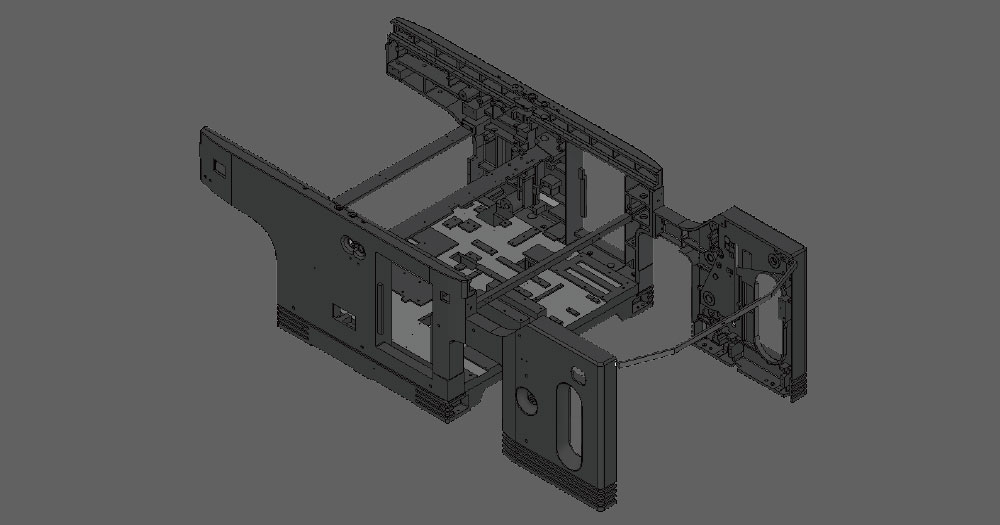

Machine frame with precision works and casting It adopts grey cast iron (HT250), found by polyester sand patterns;aging treatment, completed a one-time processing by imported large vertical type CNC,deformation little, guarantee of accuracy; ensure the long-term stable operation. |

|

Opened loading board Completed lifting steel loading board of feeder, can pull the sheet pile directly, load sheet much more easily and save operation time. |

|

|

|

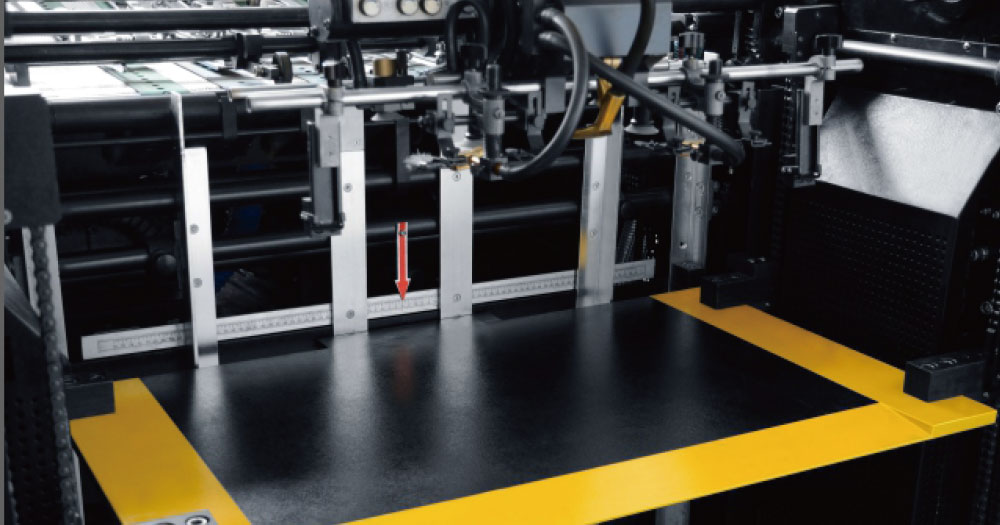

Heavy pneumatic squeegee system Integrated application of electrical, pneumatic, hydraulic technology, automatic control squeegee movement; The start printing point and end point can be set independently;The entire pressure equilibrium stability;Completely eliminates the disadvantages of the squeegee movement controlled by mechanical cam, to ensure the ink layer and definition of image constant stable whether any printing and printing |

|

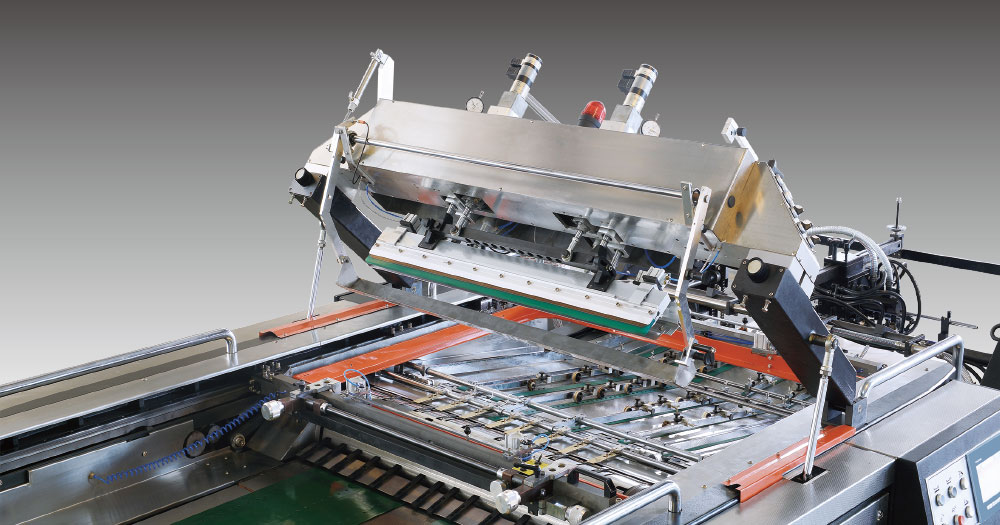

Separated screen frame structure screen frame can break away from transmission part and be pulled out, it’s easy for adjusting the registration and feeding; meanwhile it is must safer and faster for cleaning of cylinder and screen;Opto sensors automatic detection system to ensure the reliability of the action and avoid rack breakage or damage of main drive; |

|

|

| options | ||

|

||

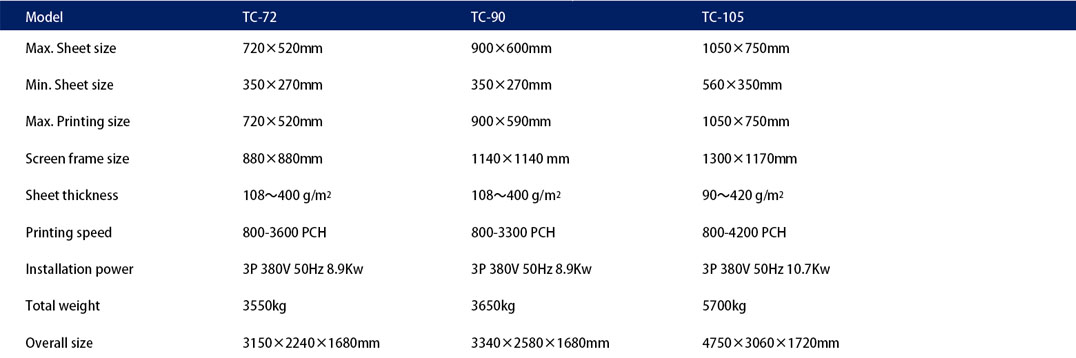

| Technical data | ||

|

||

| Application | ||

|

||

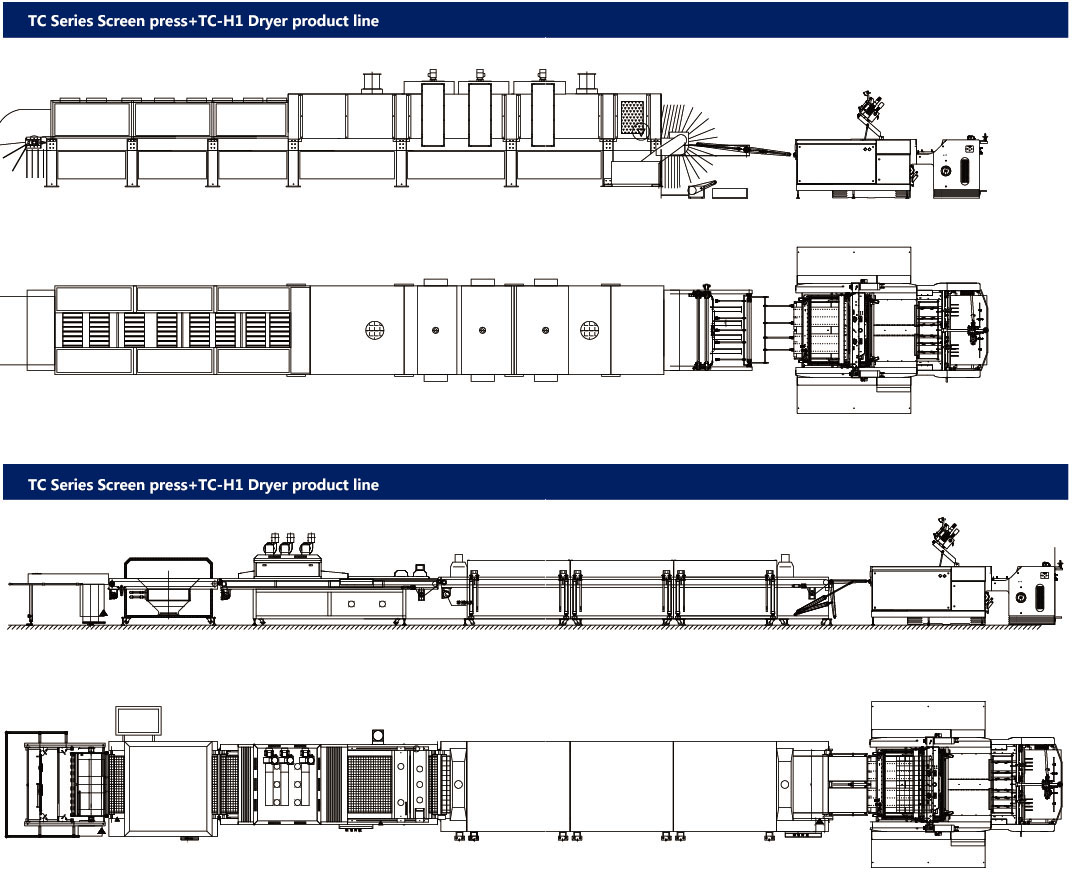

| Diagrams | ||

|

||

| TOP > | ||